At Him Imperial

Auto Glass Works

2008

Him Imperial Auto Glass Works was established with 4 vertical tempering lines.

2012

Added first horizontal tempering glass

2014

Obtained ISO certification

2015

Underwent corporate restructure

2016

Earned BIS Part-II certification for Automotive glasses

2017

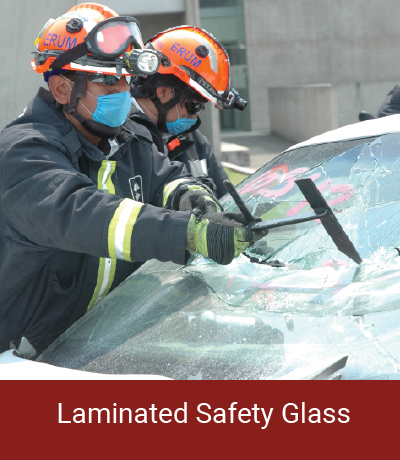

Introduced first laminated glass line

2020

- Developed India’s

largest bend laminated windshield - Acquired E11 certification for the European market

2021

- Started production of sliding aluminium window frames

- Became an IATF approved organization

2022

Commenced commercial production of bulletproof glass (Cleared all ballistic tests)

2023

Obtained EMS (Environmental Management System) and OHMS (Occupational Health & Safety Management System)

2024

- Added jumbo size tempering & insulated glass line

- Completed Supply of 15K Windshields to MSRTC

- Acquired BIS Part-I Architectural

- Received approval from US DOT for the American markets.

Million Sq. Meters of Glass Processed

Clients Served

Vehicles Catered To

Skilled Workforce

Industry Certifications

Why Him Imperial?

State of the Art Manufacturing

Our advanced facility in Kala Amb, Himachal Pradesh, is equipped with cutting-edge machinery for precise glass solutions.

Decades of Expertise

With over 30 years of experience, we have established ourselves as a leader in high-performance glass manufacturing.

Sustainability Commitment

We prioritize eco-friendly manufacturing with a 500 kW solar power plant and a water recycling system for sustainable operations.

Global Partnerships

We collaborate with top-tier international brands to ensure world-class quality and innovation.

Uncompromising Quality Standards

Our products meet globally recognized certifications, including ISO, IATF.

Our Segments

Automotive

Automotive

Industrial

Industrial

Architectural

Architectural

Our infrastructure

Located in Kala Amb, Himachal Pradesh, our state-of-the-art 1,00,000 sq. ft. manufacturing facility is equipped with cutting-edge machinery sourced globally. Operated by skilled specialists, this advanced infrastructure ensures precision and exceptional quality in every product. With a strong focus on continuous innovation and robust R&D, our design department is capable of handling diverse glass processing requirements. Key equipment includes CNC cutting machines by CMS, advanced glass bending furnaces, fully automatic edgers and washing machines, tempering machines by Mountain Glass, in-house testing labs, and one-touch operational autoclaves-enabling us to deliver unmatched glass solutions that meet global standards.

Quality Standards & Certifications

We are proud to hold certifications from prestigious organizations such as the Bureau of Indian Standards (BIS), the International Automotive Task Force (IATF), the International Organization for Standardization (ISO), the European E-Mark for automotive glass products, the U.S. Department of Transportation (DOT). Additionally, our products are rigorously tested at renowned third-party laboratories, such as the International Centre for Automotive Technology (ICAT), the Automotive Research Association of India (ARAI), the Central Institute of Road Transport (CIRT), and the National Forensic Sciences University (NFSU) .

Our Blogs

Our Clients

Our clients include some of the most prominent players in the Automotive, Architectural, and Industrial sectors who vouch for our quality solutions.