Toughened glass explained:

Features, benefits, and applications

Glass has evolved to become one of the most essential materials in construction, automotive, chemical, pharmaceuticals and several other industries. Laminated glass and toughened glass are the most commonly used types of glass in the building and automotive industry. These offer a high level of safety and security for a range of various domestic and industrial applications.

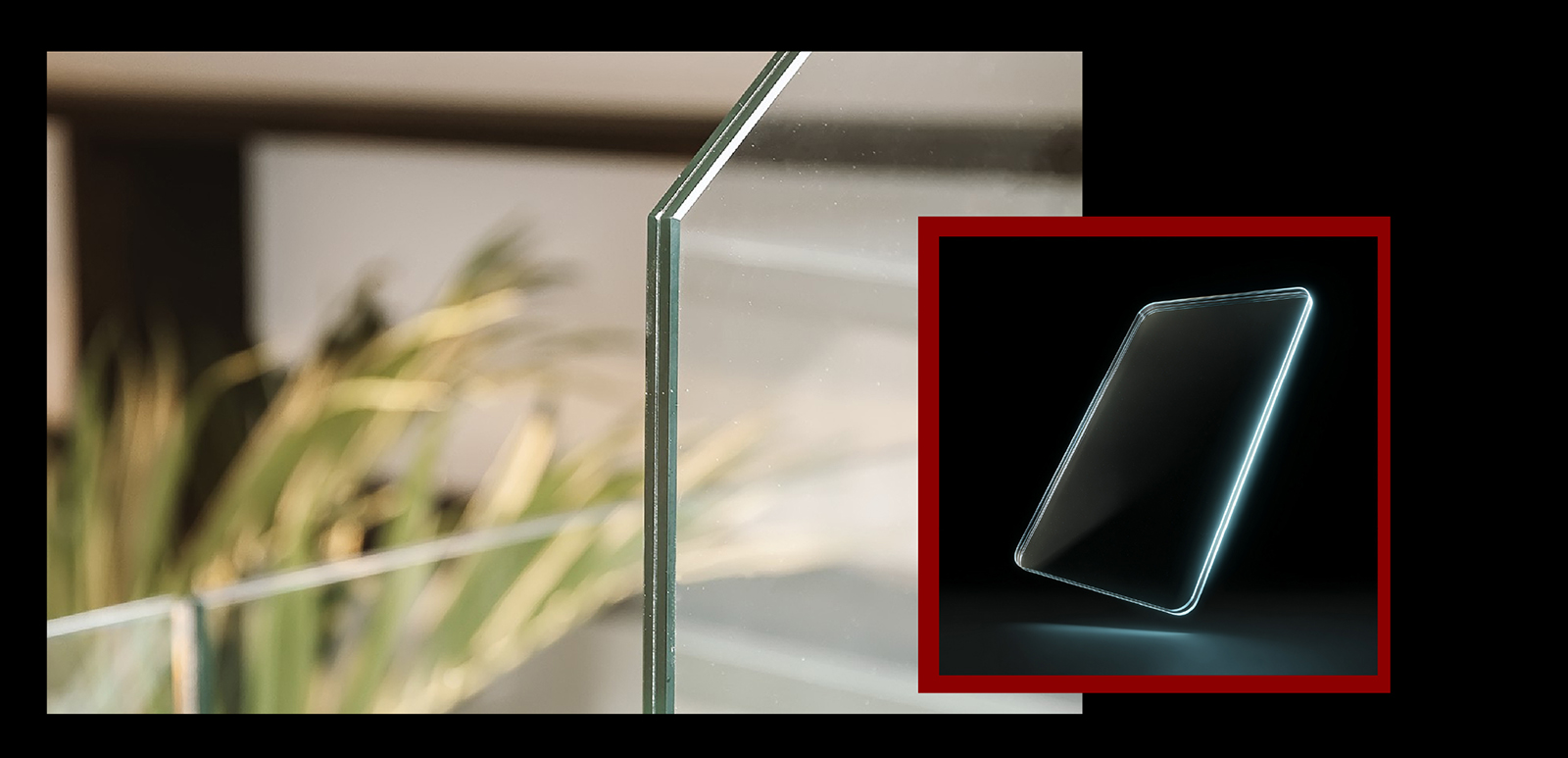

Toughened glass

Toughened glass, also known as tempered glass, is created by heating regular glass to a high temperature of 650°C and then cooling it quickly. The process makes it tough and up to 400% -500% more resistant to heat and impact when compared with ordinary glass.

Since it is heat treated and rapidly cooled, the glass produces distinct physical properties. The glass displays compressive stress on the surface and enhanced bending strength and has to be toughened before being cut to the correct size or shape.

The process of toughening enhances the structural durability and thermal strength of the end product and increases its resilience and capacity to withstand heat. One important aspect to note is that the glass cannot be recut once it is toughened and it has to be cut prior to the process of toughening. Once the glass is specially treated, it breaks into small, blunt pieces under impact which makes them safer than the shards of normal glass.

Both toughened glass and laminated glass are manufactured from float glass (also known as annealed glass). Float glass is created when molten glass cools down slowly in a controlled environment. Once produced, the clear float glass is cut to size and then subjected to further processes like tempering.

The toughening process

The glass is carried using rollers through a furnace, which help to conduct the heat. Coils enable radiation to ensure the glass is heated evenly on all sides. This is then cooled by blasting air on both the surfaces.

Attributes of toughened glass

– Toughened glass has a higher thermal strength and withstands temperatures up to 250°C.

– The basic characteristics of glass like light transmission or solar heat reflection are not altered and remain the same as with glass.

– The glass once toughened cannot be cut or altered.

– Toughened glass possesses an impact resistance that is 5 times stronger compared with the regular float glass. In the event of breakage, the surface disintegrates into small, blunt pieces.

Toughened glass – uses

Toughened glass is safe, secure and durable considering that it goes through a special process to emerge stronger. The glass is extensively used in various applications such as:

Building and construction – Considering that toughened glass is safe, strong and durable it is commonly used in doors, facades, staircases, balustrades, and partitions. Considering that it does not break easily, resists impact and splinters into harmless pieces and not sharp shards like it happens with regular glass, toughened glass is a favourite of architects and interior designers.

Automotive Industry – Toughened glass is widely used in the automotive industry in the manufacture of windshields and rear view mirrors. Its impact resistance and safety features make it the perfect choice for such applications.

Furniture and décor – Toughened glass is gaining popularity in furniture and interior decoration – as table tops for centre tables and dining tables, shelves, cabinets and partitions. Toughened glass offers the much required durability and safety and is less prone to breaking.

Solar energy – Toughened glass is used in the manufacturing of solar panels. This provides the much needed durability, as it is impact resistant and resists harsh weather conditions and extreme temperatures.

Him Imperial – Pushing the envelope of innovation in glass

Him Imperial Auto Glass Works is one of India’s leading manufacturers of glass and a complete glass solutions company. Him Imperial produces several varieties of glass for various applications and is the preferred choice of India’s leading architects and interior design consultants. We follow proven practices and manufacturing methodologies and are committed to creating products that align with the various eco-friendly initiatives being pursued by the global construction ecosystem.

Established in 2008 in Kala Amb, Himachal Pradesh, Him Imperial manufactures to exacting internal standards using the finest raw materials and processes. We are an ISO 9001:2015 certified company and our products’ quality standards are approved/verified by ARAI (THE AUTOMOTIVE RESEARCH ASSOCIATION OF INDIA), ICAT (INTERNATIONAL CENTRE OF AUTOMOTIVE TECHNOLOGY), BIS (BUREAU OF INDIA STANDARDS) & IATF (TS). We are a European Union (E+ Marking) certified company.

Our manufacturing facilities incorporate modern machinery and a full-fledged testing lab with sophisticated equipment. We have developed a high level of competence in product development that includes in-house tool design. Today we are a widely recognised automotive and construction glass solutions company and produce one of the largest spans of laminated glass (2000 * 3000 mm wide) for front windshields of heavy vehicles.

Since inception, we have worked to forge long-term relationships with our customers and are driven by the core values of integrity, transparency and commitment to quality. We are proud to have some of the best known names in the industry for customers – leading coach builders, state road transport corporations, heavy engineering equipment manufacturers, reputed builders and developers, prestigious manufacturers of buses, cars and trucks among others, who vouch for our toughened and laminated glass offerings.

To learn more about our offerings in toughened glass and our other range of products, visit us at www.himimperial.in.